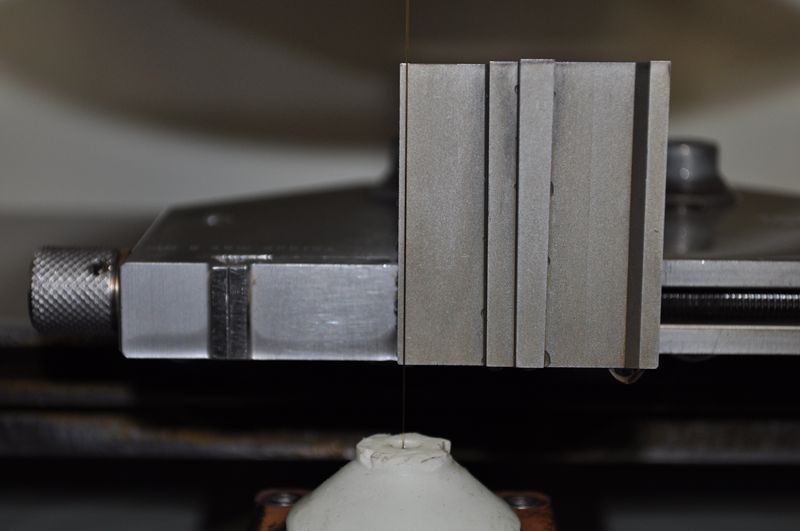

EDM Machining

At M.A.R.’s we provide Wire EDM services. With the ability to cut/burn though any conductive material with Tight tolerances and near perfect repeatability, we leverage our EDMing capacity in several ways. The First and most obvious way is by be ability to manufacture parts that require wire EDMing completely in house. The second and more common way in w we take advantage of this capability in being able to make specialty tooling in house.

The use of the EDM for custom tooling allows us to engineer custom cutting tools for each part which results in faster cycle times with extra accuracy and and consistency. With this tool making being “in-house” we are able to make new or updated tools with next to no lead time at a very low cost. The Low tooling cost paired with the faster per piece cycle time leads to a lower cost of production with is passed on to our valued customers!

Equipment Specifications

| Mitsubishi FX 10 Wire EDM | 12” x 12” x 6” Table Surface Finishes: Less than 0.15 µm Ra Wide / Large table travel up to 13.7" x 9.84" Cutting head: "Z axis" heights up to 8.66” |

| Other Equipment | 1 – Burgmaster turret drill 1 –Nicholes twin mill 2 – Hardinge tool room lathes 3 – Dumore Automatic drills 4 – Cincinnati Rise and Fall mills 5 – Micro servo drills 5 – Powermate tapping machines 6 – Bridgeport mills 6 – Hardinge turret lathes 7 – Hardinge bradmatics Misc – Drills, Sanders, Micro Sandblasting |